- Research Projects

Summary of Nextgreen’s R&D Projects

Nurturing the Future With Biomass – Nextgreen’s Biofertilizers for Sustainable Agriculture

Nextgreen is at the forefront of sustainable agricultural innovation, dedicated to advancing global sustainability through the reduction of waste and enhancement of resource efficiency.

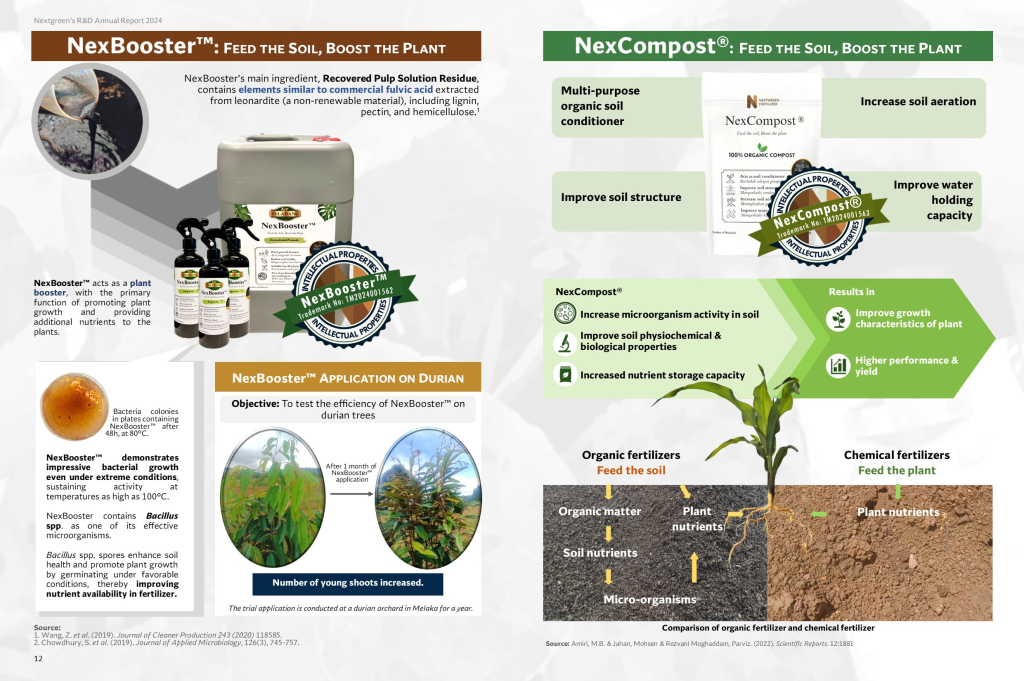

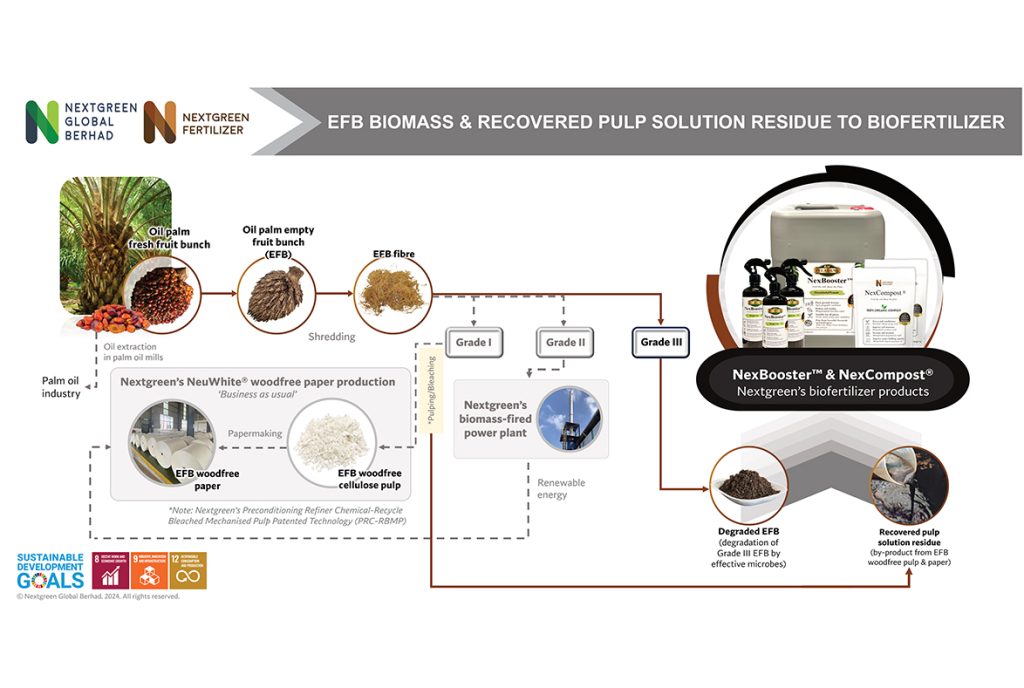

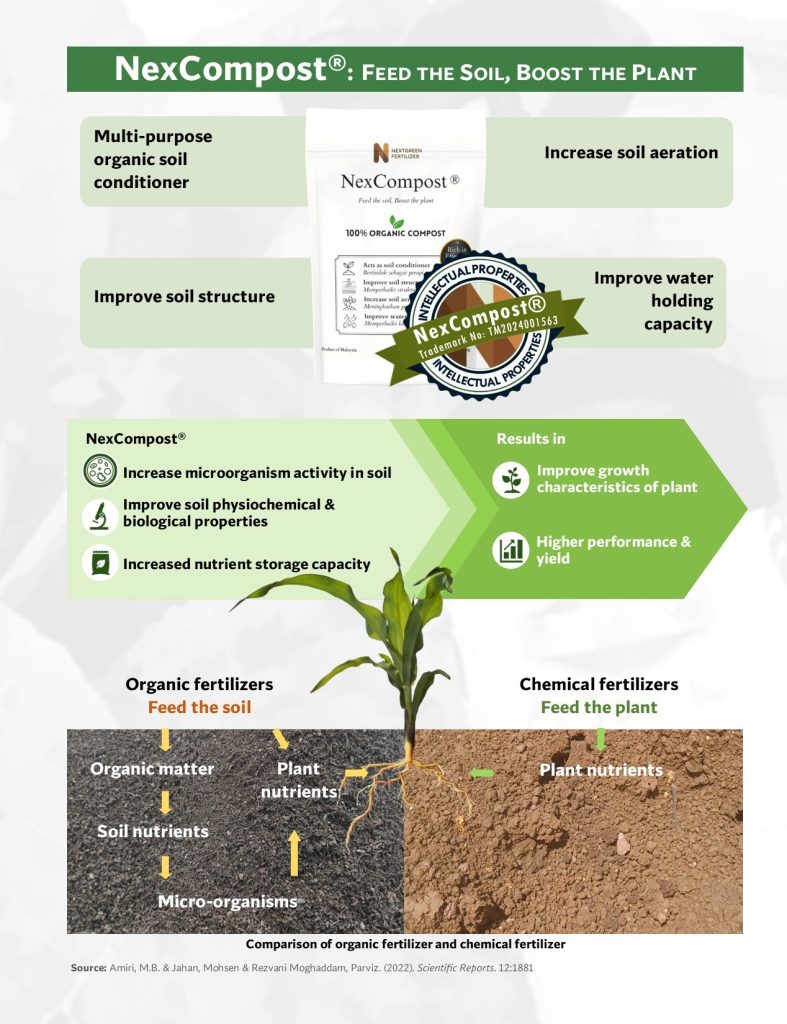

As part of this commitment, Nextgreen has successfully developed two innovative biofertilizers derived from pulp manufacturing by-products: NexBooster™ and NexCompost®. NexBooster™ is created from recovered pulp solution residue, a by-product of pulp manufacturing, while NexCompost® is derived from degraded empty fruit bunches (EFB). Both biofertilizers are produced through fermentation and composting processes using in-house effective microorganisms, respectively. The goal of these products is to support sustainable agriculture practices by reducing the environmental impact of traditional chemical fertilizers, improving long-term soil fertility, and promoting a healthier ecosystem.

Nextgreen has conducted extensive trials to evaluate the effectiveness of NexBooster™ across a wide variety of plants. Notably, trials on paddy crops—an essential staple in Malaysia—demonstrated remarkable results. Paddy treated with NexBooster™ exhibited accelerated growth, particularly in root development, with longer roots, increased root density, and larger stems.

Currently, Nextgreen is in the process of evaluating the effectiveness of its innovative biofertilizers on various crops, including oil palm, durian, bok choy, and chili. Through these initiatives, Nextgreen aims to foster sustainable practices among farmers and the agricultural industry in Malaysia, paving the way for a greener future and a healthier planet.

As part of this commitment, Nextgreen has successfully developed two innovative biofertilizers derived from pulp manufacturing by-products: NexBooster™ and NexCompost®. NexBooster™ is created from recovered pulp solution residue, a by-product of pulp manufacturing, while NexCompost® is derived from degraded empty fruit bunches (EFB). Both biofertilizers are produced through fermentation and composting processes using in-house effective microorganisms, respectively. The goal of these products is to support sustainable agriculture practices by reducing the environmental impact of traditional chemical fertilizers, improving long-term soil fertility, and promoting a healthier ecosystem.

Nextgreen has conducted extensive trials to evaluate the effectiveness of NexBooster™ across a wide variety of plants. Notably, trials on paddy crops—an essential staple in Malaysia—demonstrated remarkable results. Paddy treated with NexBooster™ exhibited accelerated growth, particularly in root development, with longer roots, increased root density, and larger stems.

Currently, Nextgreen is in the process of evaluating the effectiveness of its innovative biofertilizers on various crops, including oil palm, durian, bok choy, and chili. Through these initiatives, Nextgreen aims to foster sustainable practices among farmers and the agricultural industry in Malaysia, paving the way for a greener future and a healthier planet.

Mapping Our Footprint: A Commitment to The Planet - Carbon Footprint (CFP) Assessment, Verification, & Certification For Empty Fruit Bunches (EFB)-Based Products

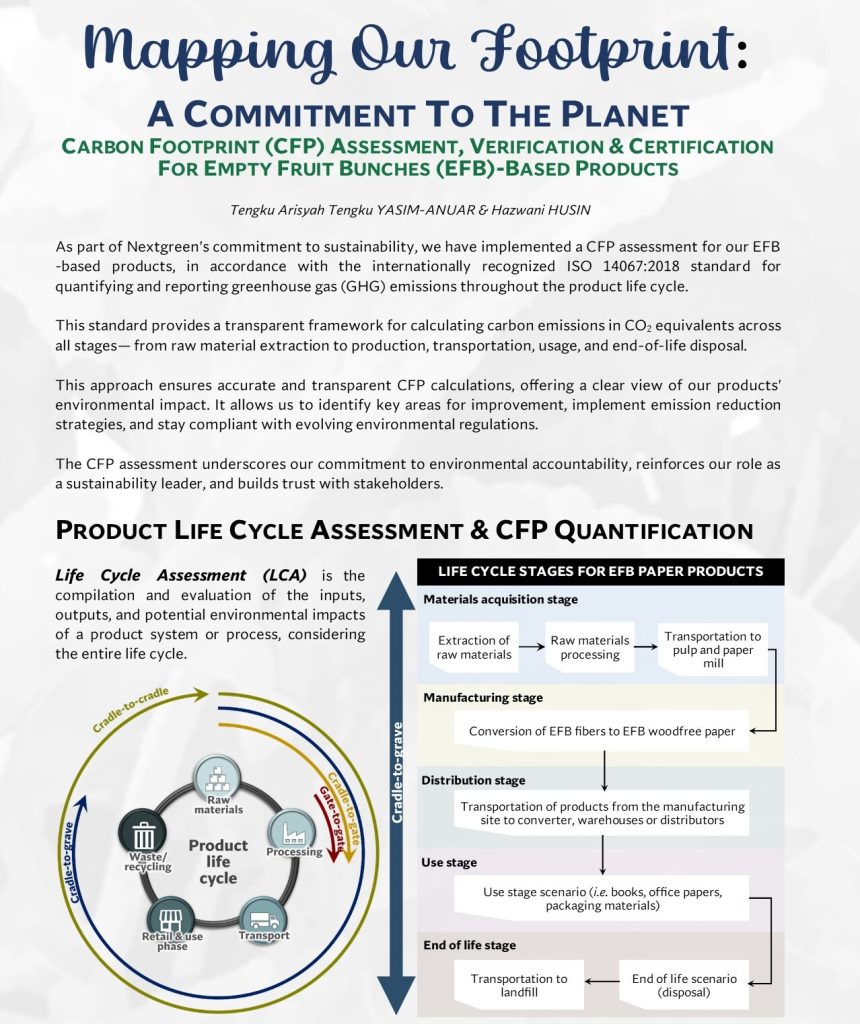

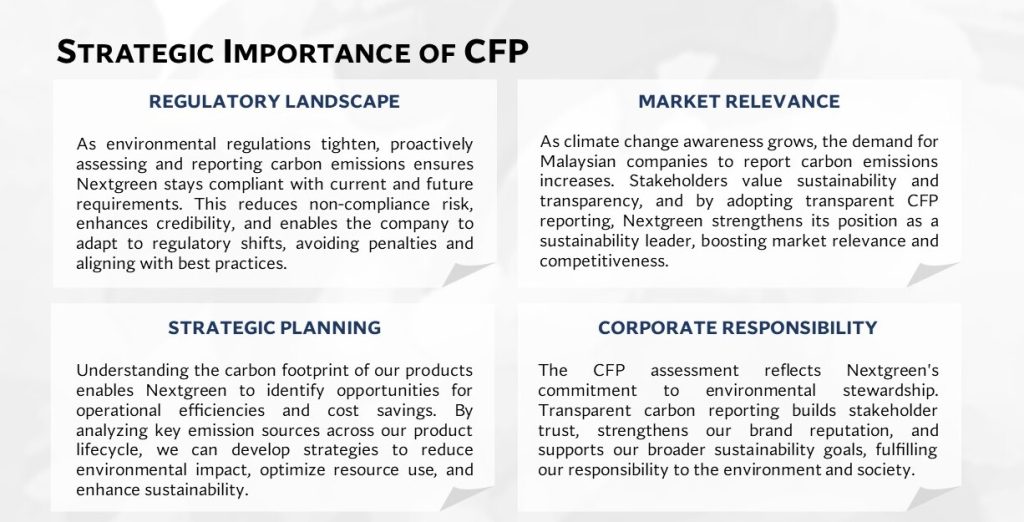

As part of Nextgreen's unwavering commitment to sustainability, we have initiated a comprehensive Carbon Footprint (CFP) assessment for our empty fruit bunch (EFB)-based products, adhering to the internationally recognized ISO 14067:2018 standard. This assessment demonstrates Nextgreen's dedication to environmental stewardship and ensures that we are transparent in our carbon reporting, which helps build stakeholder trust, strengthens our brand reputation, and supports our broader sustainability goals.

Currently, our R&D team is focused on the meticulous collection of data related to the carbon footprint of our EFB-based products at every stage of our operations within our flagship facility, the Green Technology Park. This data collection is crucial for obtaining certifications that validate our carbon emissions across the product life cycle. Through this assessment, we can identify key areas for improvement, implement effective emission reduction strategies, and remain compliant with evolving environmental regulations.

Once the data collection phase is complete, we will focus on generating the CFP report, which will quantify our products' carbon footprint. We look forward to sharing future updates that will include a detailed report of our findings and the planned actions based on the assessment. This effort not only reinforces our commitment to environmental accountability but also solidifies our position as a leader in sustainability within the industry.

Currently, our R&D team is focused on the meticulous collection of data related to the carbon footprint of our EFB-based products at every stage of our operations within our flagship facility, the Green Technology Park. This data collection is crucial for obtaining certifications that validate our carbon emissions across the product life cycle. Through this assessment, we can identify key areas for improvement, implement effective emission reduction strategies, and remain compliant with evolving environmental regulations.

Once the data collection phase is complete, we will focus on generating the CFP report, which will quantify our products' carbon footprint. We look forward to sharing future updates that will include a detailed report of our findings and the planned actions based on the assessment. This effort not only reinforces our commitment to environmental accountability but also solidifies our position as a leader in sustainability within the industry.

Carbon Return, Clean Gateway-Biodegradability Assessment of Commercial Woodfree Packaging

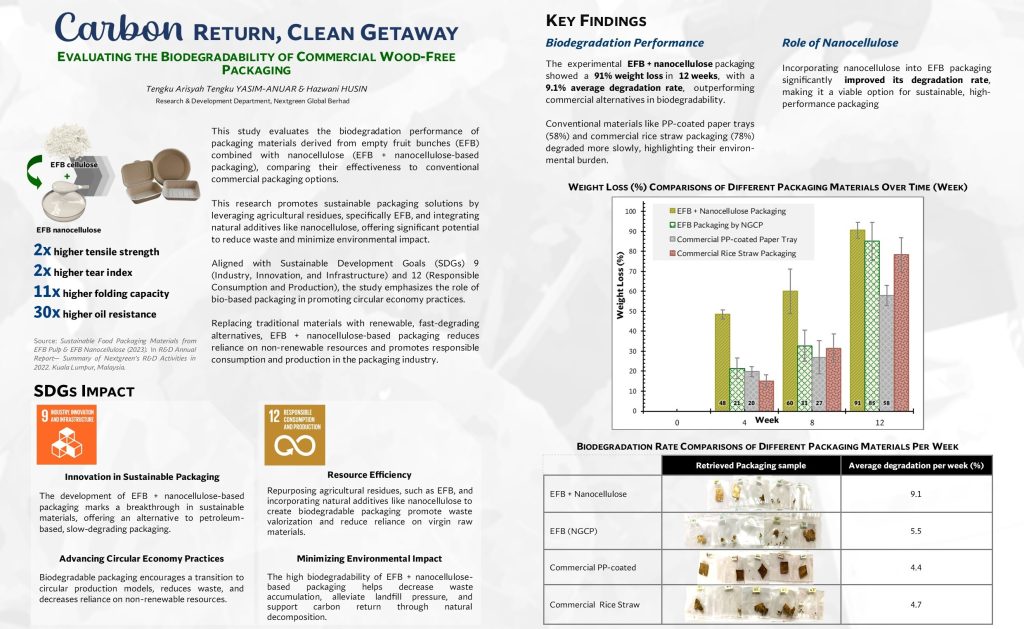

Nextgreen is committed to advancing sustainable packaging solutions through its R&D project focused on the biodegradability assessment of commercial woodfree packaging. As a pulp producer from oil palm empty fruit bunches (EFB), Nextgreen is dedicated to creating eco-friendly, biodegradable food packaging products that support a more sustainable future.

Our latest research examines the biodegradation performance of EFB-based packaging, enhanced with nanocellulose, and compares its effectiveness with conventional packaging materials. By utilizing EFB, an agricultural waste product, and integrating natural additives like nanocellulose, this project presents a promising solution for reducing waste and minimizing the environmental footprint of traditional packaging.

Preliminary results from our experiments show that the EFB + nanocellulose packaging achieved a remarkable 91% weight loss over 12 weeks, with an average degradation rate of 9.1%. This outperforms conventional materials, such as PP-coated paper trays (58%) and commercial rice straw packaging (78%), underscoring the environmental benefits of our innovative solution.

By replacing traditional packaging with renewable, fast-degrading alternatives, we are contributing to responsible consumption and production within the packaging industry. This initiative is aligned with Nextgreen’s mission to produce zero-waste, environmentally responsible products, benefiting both stakeholders and society as a whole.

Our latest research examines the biodegradation performance of EFB-based packaging, enhanced with nanocellulose, and compares its effectiveness with conventional packaging materials. By utilizing EFB, an agricultural waste product, and integrating natural additives like nanocellulose, this project presents a promising solution for reducing waste and minimizing the environmental footprint of traditional packaging.

Preliminary results from our experiments show that the EFB + nanocellulose packaging achieved a remarkable 91% weight loss over 12 weeks, with an average degradation rate of 9.1%. This outperforms conventional materials, such as PP-coated paper trays (58%) and commercial rice straw packaging (78%), underscoring the environmental benefits of our innovative solution.

By replacing traditional packaging with renewable, fast-degrading alternatives, we are contributing to responsible consumption and production within the packaging industry. This initiative is aligned with Nextgreen’s mission to produce zero-waste, environmentally responsible products, benefiting both stakeholders and society as a whole.

Leveraging The Value Of Oil Palm Biomass - Evaluating Empty Fruit Bunches and Oil Palm Fronds Blend Ratios for Sustainable Paper Production

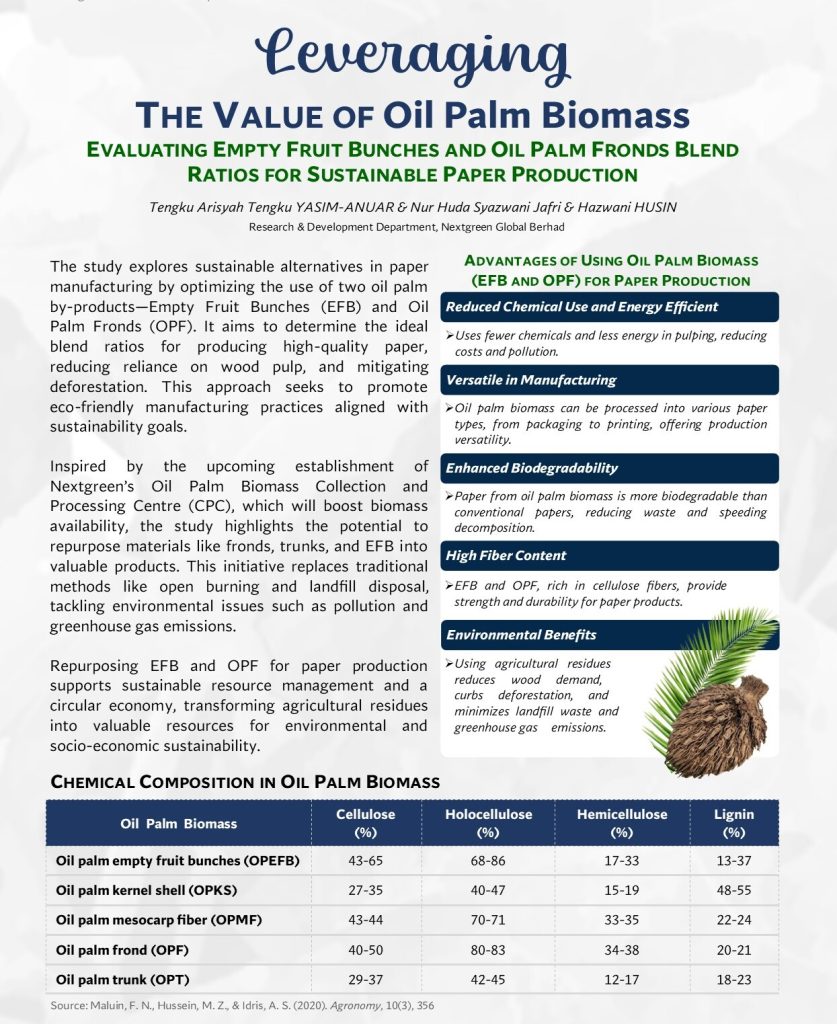

Nextgreen is dedicated to advancing research and development in sustainable practices, particularly in the field of paper manufacturing. Our latest study focuses on optimizing the use of two abundant oil palm by-products—Empty Fruit Bunches (EFB) and Oil Palm Fronds (OPF)—to identify the ideal blend ratios for producing high-quality paper. This initiative aims to reduce reliance on wood-based pulp, thereby helping to mitigate deforestation and promote eco-friendly manufacturing practices in line with sustainability goals.

The project is inspired by the upcoming establishment of Nextgreen’s Oil Palm Biomass Collection and Processing Centre (CPC), which will enhance the availability of biomass resources, including fronds, trunks, and EFB. By repurposing these materials into valuable products, we are moving away from traditional waste management methods such as open burning and landfill disposal, which contribute to pollution and greenhouse gas emissions. This approach not only addresses environmental concerns but also promotes sustainable resource management and supports a circular economy model, transforming agricultural residues into valuable resources for both environmental and socio-economic sustainability.

Our research anticipates a significant reduction in the dependency on wood fibers for paper production by utilizing the abundant raw materials available in EFB and OPF. By optimizing the EFB-OPF blend ratios, we aim to enhance the production efficiency of EFB/OPF-based papers, ensuring they meet the ISO 187:1990 certification standards for pulp and paper manufacturing. Through this innovative approach, Nextgreen is committed to fostering sustainable practices that benefit both the environment and the economy.

The project is inspired by the upcoming establishment of Nextgreen’s Oil Palm Biomass Collection and Processing Centre (CPC), which will enhance the availability of biomass resources, including fronds, trunks, and EFB. By repurposing these materials into valuable products, we are moving away from traditional waste management methods such as open burning and landfill disposal, which contribute to pollution and greenhouse gas emissions. This approach not only addresses environmental concerns but also promotes sustainable resource management and supports a circular economy model, transforming agricultural residues into valuable resources for both environmental and socio-economic sustainability.

Our research anticipates a significant reduction in the dependency on wood fibers for paper production by utilizing the abundant raw materials available in EFB and OPF. By optimizing the EFB-OPF blend ratios, we aim to enhance the production efficiency of EFB/OPF-based papers, ensuring they meet the ISO 187:1990 certification standards for pulp and paper manufacturing. Through this innovative approach, Nextgreen is committed to fostering sustainable practices that benefit both the environment and the economy.

Sustainable food packaging materials from EFB pulp & nanocellulose

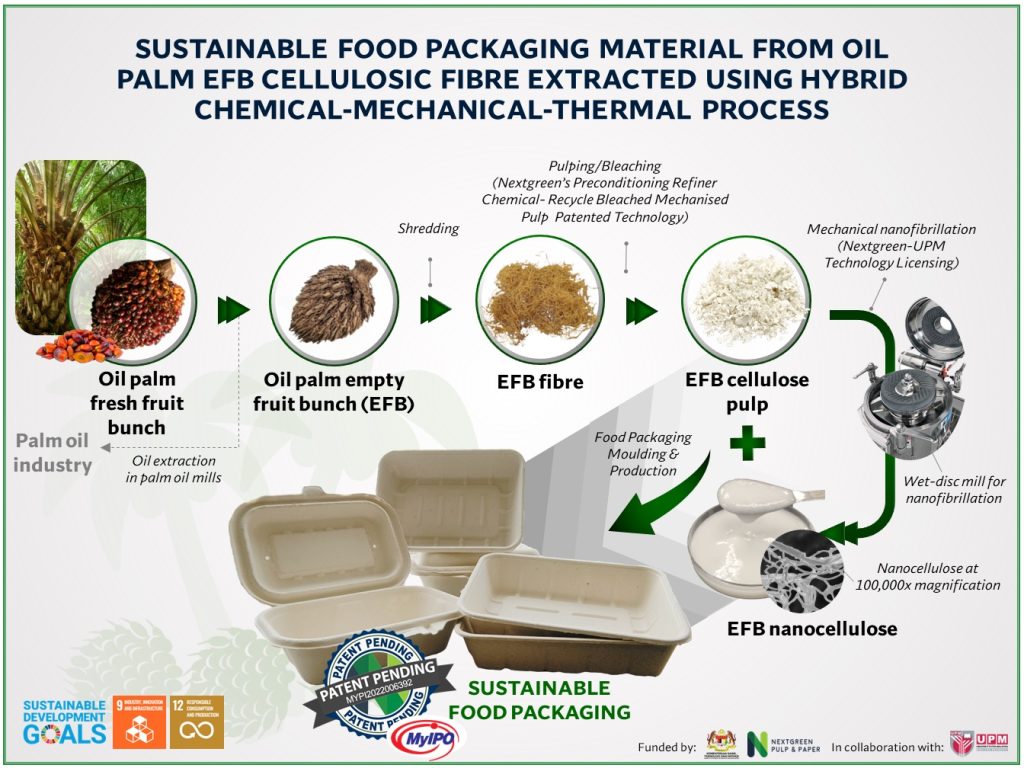

As a pulp producer from EFB, Nextgreen aims to create a green, environmentally friendly, and biodegradable food packaging product, which would support the Malaysian government’s goal of reducing the use of single-use plastics. This RM4.4 million project, started in July 2019 and ended in November 2022, and was co-funded by the Ministry of Science, Technology, and Innovation (MOSTI) and Nextgreen. Together with Universiti Putra Malaysia (UPM), Nextgreen utilised the oil palm EFB as a main raw material for the development of sustainable food packaging.

This MOSTI-Nextgreen-UPM collaboration is aimed at maximising the potential of nanocellulose which is made from the EFB as an advanced nanomaterial for enhancing the mechanical and water barrier properties of EFB-based food packaging. Aligned with Nextgreen’s mission of producing a green product with zero waste that can benefit stakeholders and society as a whole, the Social Return on Investment (SROI) forecast indicates that Nextgreen will achieve its goals of transforming stakeholders' lives and conditions, not only economically, but also socially and environmentally.

This MOSTI-Nextgreen-UPM collaboration is aimed at maximising the potential of nanocellulose which is made from the EFB as an advanced nanomaterial for enhancing the mechanical and water barrier properties of EFB-based food packaging. Aligned with Nextgreen’s mission of producing a green product with zero waste that can benefit stakeholders and society as a whole, the Social Return on Investment (SROI) forecast indicates that Nextgreen will achieve its goals of transforming stakeholders' lives and conditions, not only economically, but also socially and environmentally.

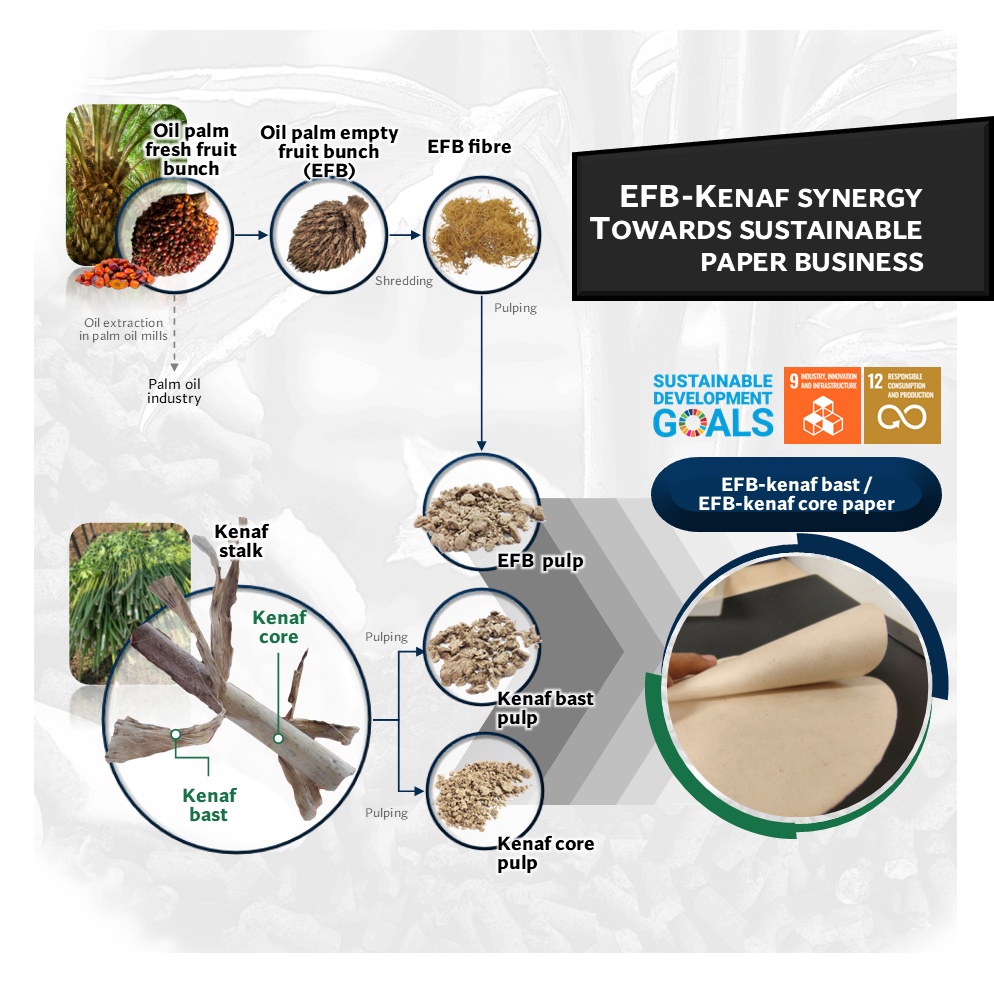

Paper production from empty fruit bunches (EFB) and kenaf

Nextgreen in collaboration with Universiti Teknologi MARA (UiTM) aims to promote green technology for pulp and paper making by using a non-toxic process that may contribute to less energy and water consumption. This three-year project commenced on August 2021, and anticipates the reduction of wood fibers dependency for paper making process by considering the abundant raw materials in the form of EFB and blending it with the fast-growing kenaf whole stem fibers. Through the optimisation of the EFB-kenaf ratio, we could achieve the enhanced production efficiency of the EFB/kenaf papers that meets the ISO 187:1990 certification, the standard for pulp and paper manufacturing.

Conversion of black liquor to lignin for adhesive production

Nextgreen is working with a group of Shaanxi University of Science and Technology (SUST), China researchers since 2018 to develop an environmentally and industrially friendly process to extract lignin from black liquor, which can be used to produce bio-adhesives. This project concluded in 2022 and foresees the promising potential of black liquor, a pulp and paper mill-generated waste as a feedstock for lignin production. The use of black liquor derived lignin to replace harmful precursors in adhesive production such as formaldehyde and petroleum-derived phenol promotes responsible and sustainable production in terms of the efficient use of renewable and environment-friendly resources.

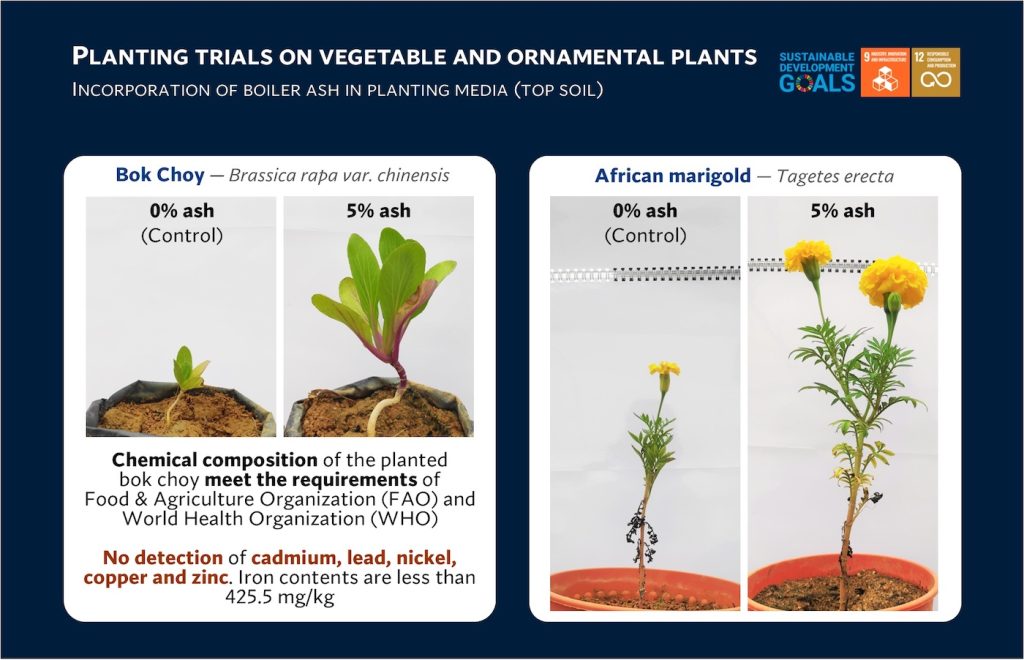

Utilisation of EFB boiler ash as soil conditioner for planting

NGPP uses EFB as a combustion material for the boiler. The ash generated could be used for value-added purposes as EFB ashes often contained high alkalinity and various nutrient contents that can be good for soil improvement and improving crop growth. This six-month project observed bigger, taller and more leaves number in both vegetable and ornamental plants. In addition, the bok choy chemical composition meets the requirements of Food & Agriculture Organization (FAO) and World Health Organization (WHO) indicating safe use of the EFB ash as part of planting medium or soil conditioner.

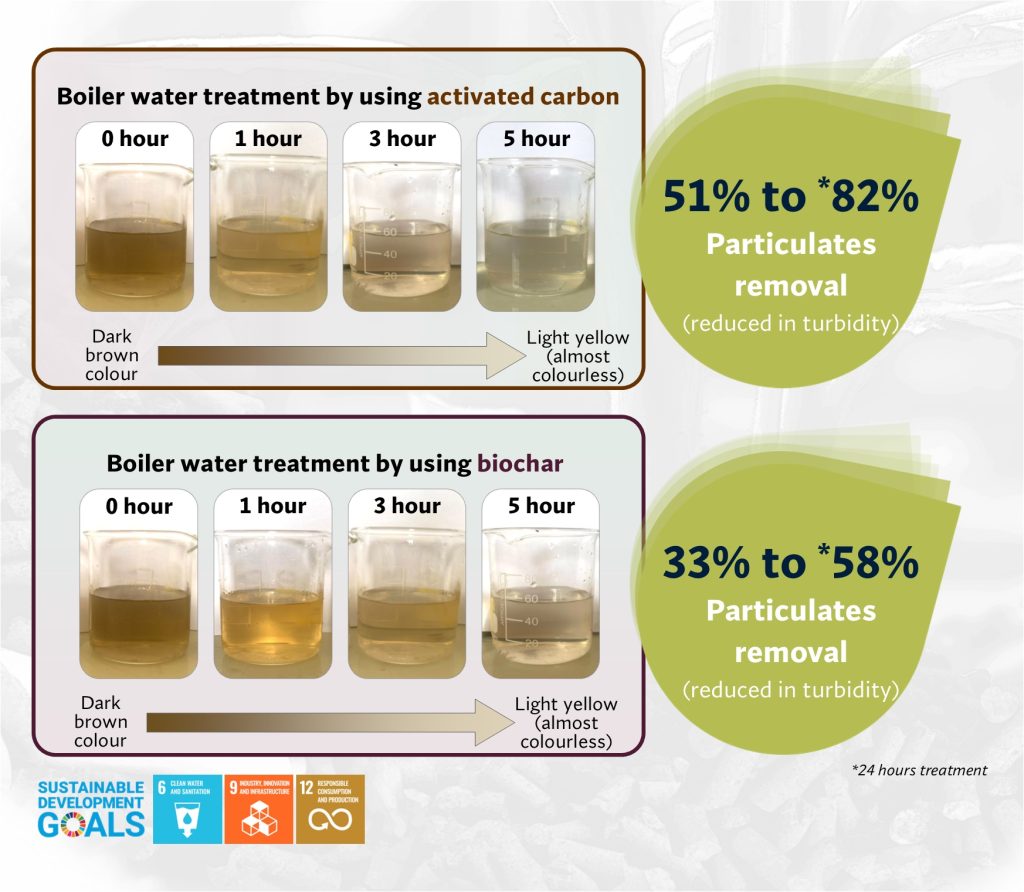

Biochar & activated carbon for boiler’s discharged water treatment

Nextgreen uses a closed-loop wet scrubber water system as an effective air pollution control device to remove particles and/or gases from the boilers, as well as to prevent a variety of pollutants from being released into the atmosphere. The Nextgreen R&D team conducted a water discharge treatment experiment to evaluate potential utilisation of bioadsorbent derived from biomass — activated carbon and biochar to remove contaminants in the discharged boiler water. The lab scale findings suggest up to 82% particulates removal indicating potential implementation of these bioadsorbent in the wastewater treatment system. The treated water could also be reused in the boiler wet-scrubber system, enhancing the efficient use of resources in Nextgreen’s mills operation.