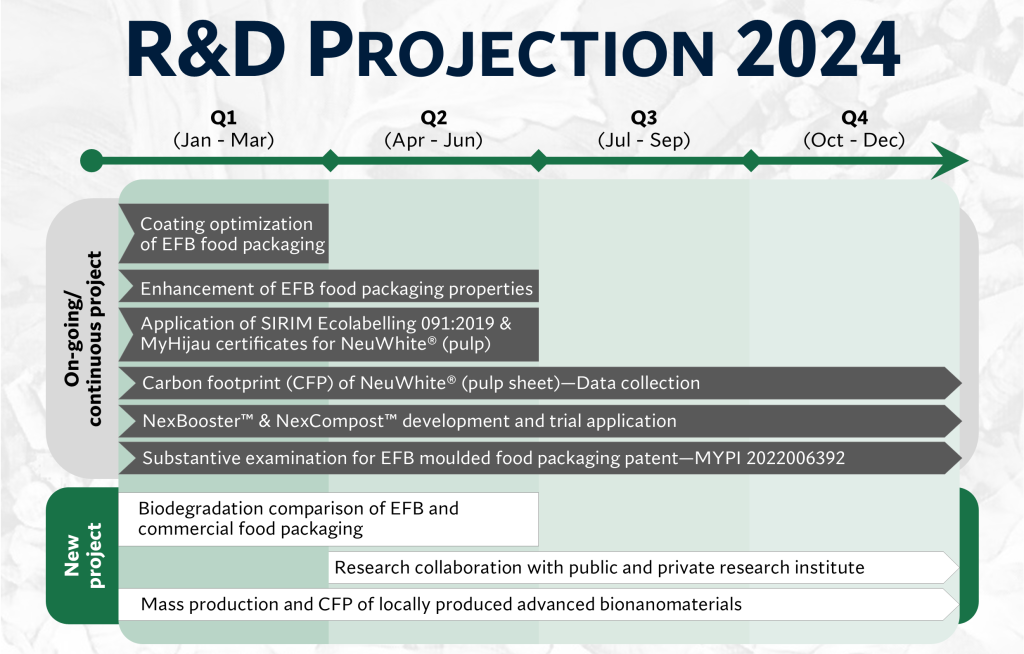

- Projection 2024

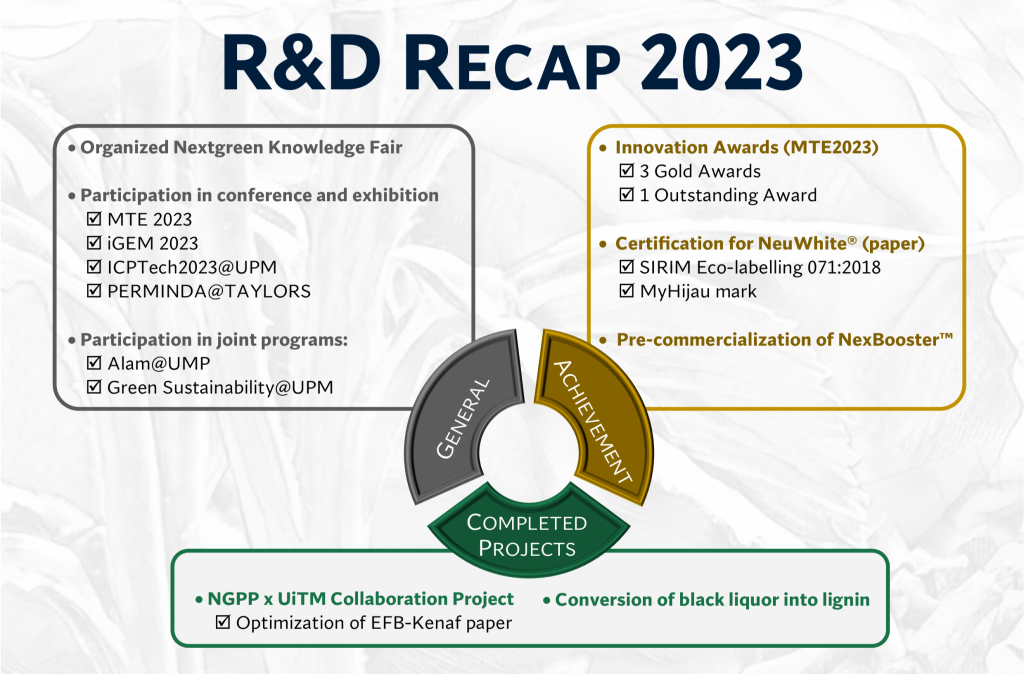

- Recap 2023

Mechanical & physical properties of EFB pulp/nanocellulose moulded food packaging

Tensile strength (Nm/g)

EFB pulp only 18%

EFB pulp + EFB nanocellulose 28%

Tear Index (mN.m2/g)

EFB pulp only 4%

EFB pulp + EFB nanocellulose 8%

Folding

EFB pulp only 6%

EFB pulp + EFB nanocellulose 45%

Oil-break-through (min)

EFB pulp only

EFB pulp + EFB nanocellulose 15%

Nanocellulose in EFB Pulp

0

x

Higher Tensile Strength

0

x

Higher Tear Index

0

x

Higher Folding Capacity

0

x

Higher Oil Resistance

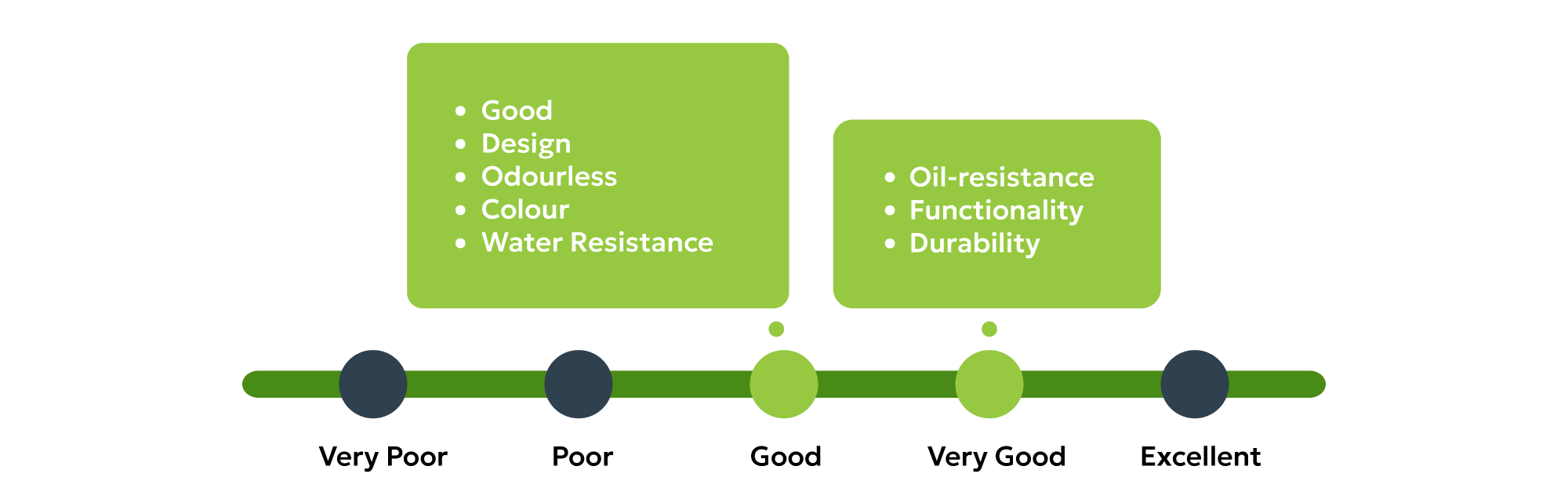

PRODUCT ACCEPTANCE STUDY

Objective: To investigate business operators’ and consumers’ perceptions on EFB pulp/ nanocellulose food packaging

91% of the company intends to use and buy eco-friendly product packaging in the future

Company demonstrated a promising market segment in terms of purchase intention

The effects of factors on product acceptance is stronger in the company’s study than in the user study

Price is the most important factor for company, but product quality is the most important for user

Top 3 characteristics:

– Does not produce harmful derivatives

– Non-toxic

– Water resistance

The market appeal of the products (willingness to pay) is stronger in the user study, than in the company study

MARKET TESTING STUDY

Objective: To identify customer’s opinions on green food packaging (GTP)

Respondents willing to use GFP if 89% the quality of GFP is decent, in an effort to preserve the environment

89%

Respondents are currently using GFP for their product, partially.

75%

Respondents foresee that GFP can give added value to their product

44%

Objective: To identify customer’s opinions on green food packaging (GTP)